Your Ultimate Selvedge Denim Material Handbook

A single pair of vintage Levi’s 501s from the 1940s recently sold for $87,400 at auction. What caused these jeans to outprice a luxury vehicle? It’s all due to their selvedge denim build.

This high-end denim stands for more than simple material. It transports us back to when James Dean sported his 501s in Rebel Without a Cause, and Marlon Brando set the standard for cool in The Wild One. These cultural icons didn’t just wear jeans. They sported black selvedge denim fabric wholesale made on historic shuttle looms.

Handcrafted denim earns its moniker from the self-finished borders that stop fraying. “Selvedge” merges “self” with “edge” to denote this distinct weaving technique. Unlike mass-produced jeans, each yard of selvedge denim material takes time and skill to create.

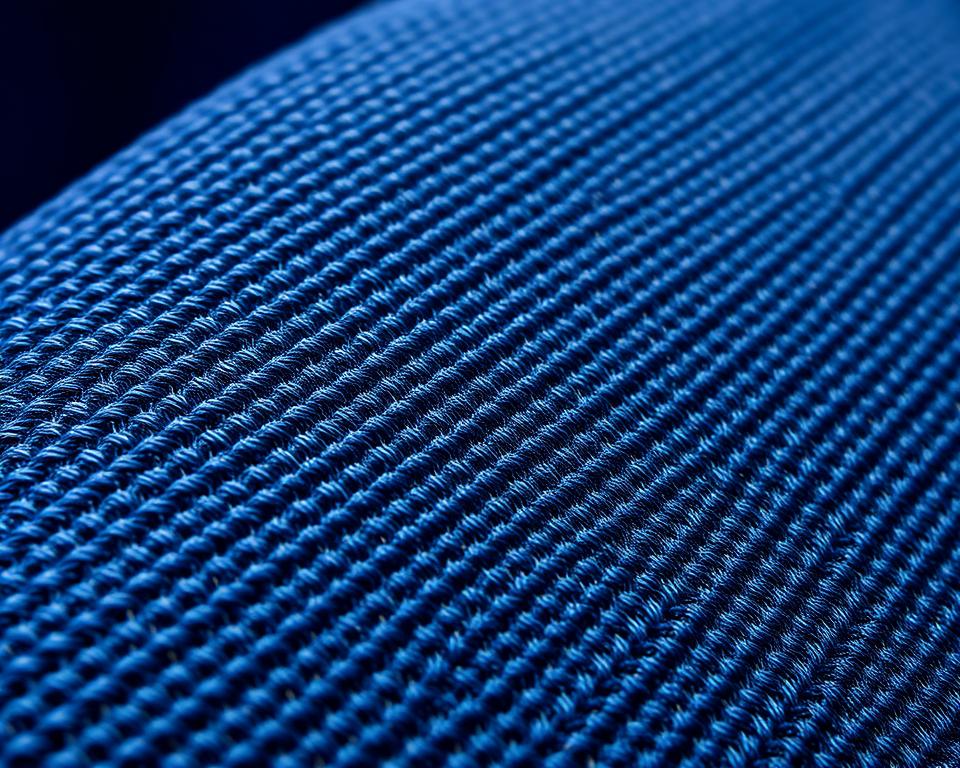

The texture tells a story through subtle irregularities and natural variations. Each pair develops its own character as the indigo fades. This individual progression renders heritage denim exceptional to collectors and style aficionados alike.

Many believe premium denim lasts longer than regular jeans. The reality, however, is more delicate. Selvedge build yields exquisite cloth with neat borders and deep texture. However, sturdiness relies on cotton caliber and heft, not merely on weaving style. What differentiates artisanal denim is its knack for aging with grace and creating singular fading designs in the long run.

Understanding Selvedge Denim Material

Selvedge denim textile differs from common denim on account of its exclusive construction and self-finished edges. It’s titled after its “self-edge,” a closely woven strip that blocks fraying. This premium material embodies a dedication to slow fashion and traditional craftsmanship, setting it apart from mass-produced denim.

The Meaning Behind Self-Edge Construction

The term “selvedge” is a blend of “self” and “edge,” describing fabric with a clean, finished border. This narrow selvage runs along both sides, removing the requirement for added finishing. Heritage mills make it about 30–32 inches wide, as opposed to modern denim’s 60-inch breadth.

Why Shuttle Looms Yield Distinct Fabric Edges

Shuttle-loomed denim’s essence stems from classic weaving machines operating more slowly. These looms weave a single weft yarn across the warp threads in one motion. This process yields:

- Natural texture variations called slubs

- A gentler hand-feel compared to contemporary denim

- Tightly bound edges that won’t fray

- Genuine irregularities prized by denim fans

Difference Between Selvedge and Standard Denim

Regular denim comes from projectile looms firing weft yarns over broader widths. This method leaves loose threads at the edges, needing overlocked seams to prevent fraying. Selvedge denim fabric, however, requires extra time in production. It provides greater longevity and a special style, meriting its loftier price tag.

Heritage and Historical Roots of Shuttle-Loomed Denim

Heritage denim’s story began in 19th-century American textile mills. Shuttle looms were central, weaving material with sealed edges to avoid fraying. This practice created indigo-dyed denim deliberately and meticulously, ensuring every yard was built with attention to detail. The fabric’s limited width turned into a signature of craft denim making.

From 19th-Century U.S. Mills to Contemporary Revival

For upwards of a century, American factories leaned on shuttle looms. Brands like Cone Mills and White Oak supplied premium denim to workwear companies. Come the 1970s, speedier projectile looms dominated, supplanting most shuttle setups. This transition was fueled by demand for lower-cost, mass-made denim. Numerous old mills shuttered or updated, letting antique looms sit idle.

Japanese Renaissance of Selvedge Denim

During the 1980s, Japanese mills resurrected U.S. shuttle looms. The Osaka Five labels headed this resurgence:

- Studio D’Artisan

- Evisu

- Fullcount

- Warehouse

- Denime

They combined American heritage style and Japanese meticulousness. They researched antique Levi’s templates, reproducing classic indigo denim textures. By the year 2000, Japan ruled the world’s artisan denim scene.

The Importance of Traditional Weaving Today

Shuttle looms create special fabric features unmatched by modern equipment. This slower method fosters subtle irregularities and fuller indigo soak. Hardcore denim fans treasure these quirks as proof of real craftsmanship.

| Shuttle Loom Features | Modern Loom Features |

|---|---|

| 29-31 inch fabric width | 60+ inch fabric width |

| 3-4 yards per hour | 15-20 yards per hour |

| Natural irregularities | Uniform texture |

| Self-finished edges | Cut edges requiring overlocking |

Making Premium Denim on Antique Looms

The creation of premium denim starts with the rhythmic motion of vintage shuttle looms. These machines differ from today’s technology. They shuttle yarn across the full width at once, binding edges without further work. This approach guarantees selvedge denim sports a neat, fray-free border.

Vintage looms weave at a slower pace, producing just 5-6 meters of slub denim daily. This is in stark contrast to modern machines, which can weave 200 meters. The slower speed benefits the yarn in several ways:

- Less tension on fibers creates a softer hand feel

- Natural irregularities remain intact for unique texture

- Varied surfaces produce signature fading

- Narrow fabric width (typically 29-32 inches) reduces cutting waste

Running these vintage looms demands expert operators. Mill workers adjust tension, monitor rhythm, and perform repairs. Each shuttle loom carries its own character. Many were built in the 1920s and require know-how passed through the ages. This hands-on approach makes shuttle-loomed denim a true artisan product.

The narrow width of dry denim from vintage looms has a practical benefit. Pant makers utilize the selvedge edge as the outrigger seam, avoiding waste. This highlights the material’s genuine build. Every bolt carries history, with slight quirks that mass output cannot match.

Raw Denim vs. Selvedge: Key Distinctions

A lot of denim fans mix up raw denim and selvedge denim. This mix-up appears during premium jean hunts. The truth is, these terms describe different aspects of denim production. Recognizing the distinction empowers you to choose wisely and admire each type’s special qualities.

Why Selvedge Isn’t Always Raw

Selvedge refers to the weaving method on vintage shuttle looms, creating self-finished edges. Raw denim means unwashed fabric straight from the mill. A selvedge raw denim distributor often carries both rinse and dry options. Brands like Naked & Famous produce selvedge jeans, sometimes pre-washed or with stretch.

The weaving technique remains the same. However, finishing transforms both the cloth’s texture and appearance.

Washed vs Unwashed Denim Options

Each denim item originates as dry denim before laundering. Mills produce both standard and selvedge versions unwashed. The main differences are:

- Raw denim develops unique fading patterns based on wear

- Pre-washed denim offers instant comfort and stable sizing

- Sanforized raw shrinks minimally post-first wash

- Unsanforized cloth contracts substantially when wet

Breaking Down Common Misconceptions

Raw denim isn’t exclusively shuttle-loomed. Modern projectile looms also produce unwashed fabric. The appeal often overlaps because buyers value durability, personalization, and craftsmanship in both selvedge and raw denim. Both types attract denim heads willing to invest time for that perfect custom fade.

How to Identify Real Selvedge Denim

If you’re shopping for rainbow selvedge denim, spotting real selvedge denim is essential. It distinguishes you from casual shoppers. Authentic selvedge denim features attributes absent in normal denim. Understanding these features ensures you’re investing in authentic premium denim.

Finding the Selvedge ID

The clearest way to spot selvedge denim is viewing the outseam. Turn up the cuff and look at the seam along the outside of the leg. Genuine selvedge denim has a clean, finished edge with colored yarns woven into the fabric. This self-finished edge eliminates the need for overlocking stitches found on regular denim.

Cuffing your jeans reveals the selvedge ID, imparting distinctive flair to your look. The tinted edge threads flow uninterrupted along the outseam, crafting that iconic denim aesthetic fans love. Regular jeans feature raw edges secured with serger stitches to avoid fraying.

Quality Construction Hallmarks

Top-tier premium denim reveals itself by key build features:

- Tight, even weaving with no loose threads

- Clean selvedge edges without additional stitching

- Stable colored yarn running the full outseam

- Heavy fabric weight characteristic of shuttle looms

Rainbow vs Redline Selvedge Distinctions

Rainbow selvedge incorporates varied colored threads in the ID, yielding a vibrant multicolor border. Redline selvedge, the most famous variety, uses red yarns for the ID and traces back to vintage American mills. These distinctive selvedge variants fetch more owing to their rarity and visual charm. Most brands proudly highlight these features in product descriptions, making authentic heritage denim easier to identify.

What Drives Artisanal Denim Prices

Newcomers are often astonished by artisanal denim price tags. A set of selvedge jeans may run three to five times higher than standard jeans.

Comprehending what drives these costs shows the actual value of premium denim.

Shuttle looms operate at a far slower rate than modern counterparts. While mass-production looms yield fabric swiftly, heritage shuttle looms turn out just 1–2 meters each hour. This slow process means a single roll of heritage denim takes days, not hours.

The slender breadth of selvedge fabric hikes up costs. Unlike standard denim, which comes in 60-inch widths, premium denim from shuttle looms is just 28-32 inches wide. Such narrowness demands extra planning and precision cutting to optimize usage.

Craft denim making happens in small runs. Firms such as Okayama’s White Oak and Kuroki favor excellence over volume. They employ master craftsmen who oversee every step:

- Hand-checking yarn tension

- Adjusting loom settings for each fabric type

- Inspecting every meter for flaws

- Managing rope-dyeing processes that take weeks

These denim makers view their craft as art. They innovate with special yarns and refine indigo dyeing recipes inherited over ages. Backing heritage denim helps mills safeguard textile legacies and artisans devoted to their work.

Black Selvedge Denim Fabric Wholesale Options

The high-end denim scene has expanded past Japan’s classic mills. U.S. labels now vie in the market, offering diverse black selvedge denim wholesale. To find the best supplier, it’s essential to understand quality markers and the origins of authentic materials.

Finding Quality Suppliers and Manufacturers

Quality suppliers emphasize heritage weaving and a deep passion for craftsmanship. When seeking a selvedge raw denim wholesale source, pick mills operating antique shuttle looms. These suppliers offer detailed fabric specs, including weight, weave pattern, and dye methods.

Gold Selvedge Denim Fabric Manufacturers to Know

Gold selvedge denim fabric manufacturers focus on premium colored ID lines, adding luxury to jeans. Top factories craft these niche fabrics in small batches, drawing boutique labels. The gold thread ID gives these fabrics a unique finish, distinguishing them from standard options.

Sourcing Specialty Fabrics Like Nep Denim

Special weaves like nep denim warrant direct sourcing links. Nep denim boasts purposeful slubs for eye-catching texture. Directly working with mills ensures access to these specialized weaves.

| Fabric Type | Minimum Order | Lead Time | Price Range per Yard |

|---|---|---|---|

| Black Selvedge | 500 yards | 6-8 weeks | $12-18 |

| Gold ID Selvedge | 300 yards | 8-10 weeks | $15-22 |

| Nep Denim | 400 yards | 10-12 weeks | $14-20 |

Selvedge Styles and Variants

Selvedge denim’s realm extends past plain indigo. Today, mills create a wide range of textures and patterns. They highlight the adaptability of shuttle-loom craftsmanship. From subtle surface variations to bold visual patterns, these fabrics offer unique character that develops beautifully with wear.

Exploring Slub Denim Texture

Slub denim’s unique textured surface originates from thick-thin yarn variations. They include thick and slim sections, producing an inherently varied cloth surface. On shuttle looms, they create slub-textured selvedge denim with random fade patterns.

Every slub denim pair evolves a distinct fade motif. The raised areas wear differently than the smooth sections, making each pair distinct.

Features of Herringbone Selvedge Denim

Herringbone selvedge cloth sports a zigzag weave reminiscent of fish skeletons. This weave creates diagonal lines that shift direction at regular intervals. This design enhances appearance and amps up the material’s toughness.

Brands like Iron Heart and The Strike Gold routinely utilize this weave in their top-tier offerings.

Striped Denim Fabric and Unique Weaves

Striped denim fabric incorporates contrasting yarns to create vertical or horizontal lines. Workrooms produce these stripes by alternating colored yarns in the weave. Notable variants include:

- Hickory stripe with alternating indigo and white

- Railroad stripe featuring thin pinstripes

- Wabash stripe with printed dots over stripes

| Fabric Type | Visual Pattern | Fade Characteristics |

|---|---|---|

| Slub Denim | Bumpy, irregular surface | High contrast, uneven fading |

| Herringbone | Zigzag diagonal lines | Subtle vertical streaking |

| Striped Denim | Alternating color bands | Pattern remains visible after fading |

Care Tips for Your Heritage Denim

Heritage denim needs particular attention to evolve its distinct personality. Unlike regular jeans, raw denim and dry denim transform with wear. They craft individual fade narratives reflecting your life.

Your first few wears in artisan denim might feel firm and odd. This is normal. The fabric needs time to soften and mold to your body shape. Some denim enthusiasts speed up this process by wearing their jeans in the shower or doing squats while damp. Others choose a slower, natural wear-in routine.

Raw denim yields its prime fades if you delay washing. Skin oils and regular friction form whiskers by the knees and honeycombs at the rear. Many owners go six months before their first wash, while some wait a full year. That patience rewards you with bold, custom fades matching your motion.

At wash time for dry denim, invert and launder in cold water. Avoid spinning and air-dry out of sunlight. Others opt for gentle hand-wash in a bathtub using a soft detergent. Steer clear of hot water and tumble drying, which may shrink and dull fades.

Your denim investment appreciates with correct maintenance. Every wear layers character, ensuring your jeans are uniquely yours. The rigid start transforms into a comfortable second skin that reflects your lifestyle and movement patterns.

Where You Can Purchase Quality Indigo Denim Now

The resurgence of selvedge denim has opened up new avenues for denim enthusiasts. Major retailers now carry indigo-dyed denim alongside specialty stores focused on premium denim and slow fashion. This helps buyers locate real selvedge choices across price ranges for any budget or taste.

Levi’s sells its 501 Original Fit Selvedge for $148, bringing heritage craft to more people. Uniqlo offers its Selvedge Straight at $50, striking a balance between style and price. If you want luxury, Buck Mason stocks Japanese Loom State Selvedge Full-Saddle Jeans for $248. Iron Heart pushes premium denim further with its 634s-18 Vintage Denim Jeans at $385 via Self Edge.

American brands like Todd Snyder and Buck Mason now compete with Japanese specialists in the selvedge denim market. They realize that classic weaving methods and excellence underpin slow-fashion success. Whether you shop digitally or in-store, quality indigo denim is now more reachable for U.S. buyers who value true craftsmanship.